Product Introduction

The Step Screen is widely recognized as an effective solution for fine screening in wastewater treatment plants. With its automated operation and minimal maintenance needs, it helps prevent downstream equipment from clogging while reducing overall system wear.

Thanks to its unique step-shaped lamellae and optimized hydraulics, this equipment ensures efficient solids removal while keeping energy and water consumption low. It’s particularly well-suited for municipal and industrial wastewater applications, especially in installations where deep channels or limited installation space are present.

Typical Applications

The Step Screen is commonly used in a variety of sewage pretreatment scenarios, including:

-

✅ Municipal wastewater treatment plants

-

✅ Residential wastewater systems

-

✅ Sewage pumping stations

-

✅ Waterworks and power plants

It is also ideal for industrial wastewater treatment, particularly in sectors such as: Textile; Printing and dyeing; Food and beverage; Fishery; Paper production; Winery and brewery; Slaughterhouse; Leather and tanning

Features & Benefits

-

1. Gentle Operation

-

Smooth and complete lifting of screenings and rocks from the channel bottom.

-

-

2. Adjustable Inclination

-

Channel installation angle ranges from 40° to 75°, adaptable to different site conditions.

-

-

3. Superior Hydraulic Performance

-

Offers high flow capacity with minimal head loss, one of the best in its class.

-

-

4. High Capture Efficiency

-

Narrow slot openings combined with a screenings mat formation ensure excellent debris removal.

-

-

5. Self-Cleaning Mechanism

-

No spray water or brushes required, thanks to its automatic self-cleansing design.

-

-

6. Low Maintenance

-

Requires no regular lubrication; simple and durable design reduces downtime.

-

-

7. Exceptional Reliability

-

Highly resistant to jamming from grit, gravel, and small stones.

-

Operation Principle

-

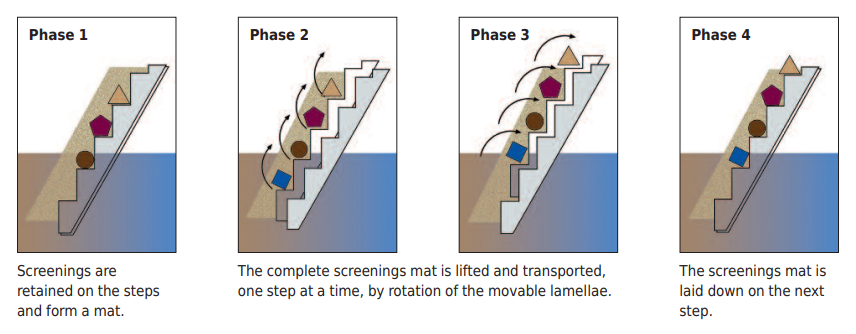

1. Screenings are retained on the inclined steps and begin forming a mat.

-

2. Through a step-by-step movement, the rotating lamellae lift the entire mat upward.

-

3. The mat is then deposited onto the next step, and the process repeats until discharge.

Technical Parameters

| Screen Width (mm) | Discharge Height (mm) | Screen Opening (mm) | Flow Capacity (L/s) |

| 500-2500 | 1500-10000 | 3,6,10 | 300-2500 |