How It Works

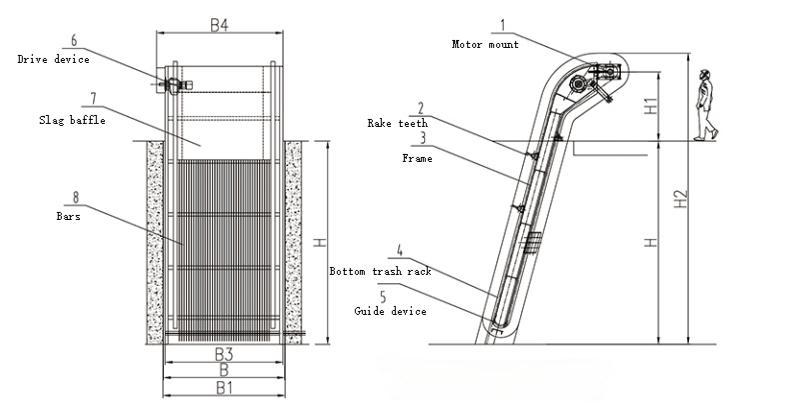

As wastewater or raw water passes through the screen, debris larger than the screen spacing is trapped. The rake teeth on the toothed rake plate insert into the gaps between the fixed bars, lifting the intercepted material upward as the drive unit rotates the traction chain.

Once the rake teeth reach the discharge point, debris falls off by gravity into a conveyor system for removal or further processing. This automatic cleaning process ensures continuous, efficient operation with minimal manual intervention.

Key Features

-

1. Reliable Drive System

-

Driven by a cycloidal pinwheel or helical gear motor

-

Features low noise, compact structure, and stable performance

-

-

2. Heavy-Duty Rake Teeth

-

Welded bevel-tipped teeth mounted on a horizontal shaft

-

Capable of lifting larger solid waste effectively

-

-

3. Robust Frame Design

-

Integral frame structure ensures high rigidity

-

Easy installation with minimal daily maintenance requirements

-

-

4. User-Friendly Operation

-

Supports on-site or remote control for flexible operation

-

-

5. Dual Safety Protection

-

Equipped with mechanical shear pins and overcurrent protection

-

Prevents equipment damage during overload conditions

-

-

6. Secondary Grating System

-

A secondary screen is installed at the bottom of the unit

-

When the rake teeth move from the rear to the front of the main screen, the secondary grating fits automatically to prevent bypass flow and ensure effective debris capture

-

Applications

-

✅Municipal and industrial wastewater treatment plants

-

✅River intakes and hydraulic pumping stations

-

✅Coarse screening before fine filtration units

-

✅Pre-treatment stages in water supply systems

Technical Parameters

| Model | HLBF-1250 | HLBF-2500 | HLBF-3500 | HLBF-4000 | HLBF-4500 | HLBF-5000 |

|

Machine width B(mm) |

1250 |

2500 |

3500 |

4000 |

4500 |

5000 |

|

Channel width B1(mm) |

B1=B+100 |

|||||

|

Mesh size b(mm) |

20~150 |

|||||

|

Installation angle |

70~80° |

|||||

|

Channel depth H(mm) |

2000~6000 (According to customer ‘s requirement.) |

|||||

|

Discharge height H1(mm) |

1000~1500 (According to customer ‘s requirement.) |

|||||

|

Running speed(m/Min) |

Around 3 |

|||||

|

Motor power N(kW) |

1.1~2.2 |

2.2~3.0 |

3.0~4.0 |

|||

|

Civil engineering demand load P1(KN) |

20 |

35 |

||||

|

Civil engineering demand load P2(KN) |

20 |

35 |

||||

|

Civil engineering demand load △P(KN) |

2.0 |

3.0 |

||||

Note: P1(P2) is calculated by H=5.0m,for every 1m H increased,then P total=P1(P2)+△P

Dimensions

Water Flow Rate

| Model | HLBF-1250 | HLBF-2500 | HLBF-3500 | HLBF-4000 | HLBF-4500 | HLBF-5000 | ||

|

Water depth before screen H3 (mm) |

3.0 |

|||||||

|

Flow rate (m/s) |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

||

|

Mesh size b (mm) |

40 |

Flow rate (l/s) |

2.53 |

5.66 |

8.06 |

9.26 |

10.46 |

11.66 |

|

50 |

2.63 |

5.88 |

8.40 |

9.60 |

10.86 |

12.09 |

||

|

60 |

2.68 |

6.00 |

8.64 |

9.93 |

11.22 |

12.51 |

||

|

70 |

2.78 |

6.24 |

8.80 |

10.14 |

11.46 |

12.75 |

||

|

80 |

2.81 |

6.30 |

8.97 |

10.29 |

11.64 |

12.96 |

||

|

90 |

2.85 |

6.36 |

9.06 |

10.41 |

11.70 |

13.11 |

||

|

100 |

2.88 |

6.45 |

9.15 |

10.53 |

11.88 |

13.26 |

||

|

110 |

2.90 |

6.48 |

9.24 |

10.62 |

12.00 |

13.35 |

||

|

120 |

2.92 |

6.54 |

9.30 |

10.68 |

12.06 |

13.47 |

||

|

130 |

2.94 |

6.57 |

9.36 |

10.74 |

12.15 |

13.53 |

||

|

140 |

2.95 |

6.60 |

9.39 |

10.80 |

12.21 |

13.59 |

||

|

150 |

2.96 |

6.63 |

9.45 |

10.86 |

12.27 |

13.65 |

||