Product Features

1. Premium Raw Materials

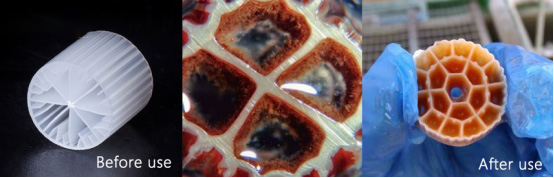

Manufactured using virgin HDPE (non-recycled), blended with a proprietary additive formula including UV inhibitors and hydrophilic agents. The food-grade polymer structure ensures high durability and excellent resistance to impact. Geometric design based on hydrodynamic principles enhances the adhesion capacity for microbial growth.

2. High Efficiency & Large Surface Area

Equipped with 20 high-speed production lines, our output rate is 1.5× faster than typical competitors. The media offers an expansive protected surface area, supporting the development of both heterotrophic and autotrophic bacteria. This dual biological capacity promotes efficient nitrification, denitrification, and dephosphorization within the biofiltration media.

3. Energy-Saving Design for Anaerobic Systems

Designed for use without supporting brackets, the media remains suspended in a fluidized state, reducing energy consumption while improving bubble shear and mixing efficiency. In comparable operating conditions, aeration requirements can be reduced by more than 10%.

Typical Applications

1. Industrial Wastewater Treatment

Used in MBBR systems to biologically remove organic matter, nitrogen, and phosphorus from wastewater produced in food, paper, textile, and chemical industries.

2. Aquaculture Wastewater

Maintains water quality in fish ponds or recirculating aquaculture systems by supporting nitrifying bacteria that reduce ammonia and nitrite levels.

3. Artificial Wetlands

Enhances pollutant degradation in constructed wetlands through efficient biofiltration, ideal for decentralized or ecological treatment systems.

4. Municipal Sewage Treatment Plants

Improves biological treatment efficiency in aerobic or anaerobic tanks, especially in IFAS or MBBR systems used in city-level sewage treatment.

Packing and Delivery

-

✔️Packing Volume: 0.1 m³/bag

-

✔️20FT Container: 28–30 m³

-

✔️40FT Container: 60 m³

-

✔️40HQ Container: 68–70 m³

Technical Parameters

| Parameter/Model | Unit | PE01 | PE02 | PE03 | PE04 | PE05 | PE06 | PE08 | PE09 | PE10 |

| Dimensions | mm | φ12*9 | φ11*7 | φ10*7 | φ16*10 | φ25*10 | φ25*10 | φ5*10 | φ15*15 | φ25*4 |

| Hole Numbers | nos. | 4 | 4 | 5 | 6 | 19 | 19 | 8 | 40 | 64 |

| Protected surface area | m2/m3 | >800 | >900 | >1000 | >800 | >500 | >500 | >3500 | >900 | >1200 |

| Density | g/cm3 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 1.02-1.05 | 1.02-1.05 | 0.96-0.98 | 0.96-0.98 |

| Packing Numbers | pcs/m3 | >630000 | >830000 | >850000 | >260000 | >97000 | >97000 | >2000000 | >230000 | >210000 |

| Porosity | % | >85 | >85 | >85 | >85 | >90 | >90 | >80 | >85 | >85 |

| Dosing Ratio | % | 15-67 | 15-68 | 15-70 | 15-67 | 15-65 | 15-65 | 15-70 | 15-65 | 15-65 |

| Membrane Formation Time | days | 3--15 | 3--15 | 3--15 | 3--15 | 3--15 | 3--15 | 3--15 | 3--15 | 3--15 |

| Nitrification Efficiency | gNH₄-N/m³·d | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 500-1400 | 500-1400 | 500-1400 |

| BOD₅ Oxidation Efficiency | gBOD₅/m³·d | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2500-15000 | 2500-15000 | 2500-20000 |

| COD Oxidation Efficiency | gCOD/m³·d | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2500-20000 | 2500-20000 | 2500-20000 |

| Applicable Temperature | ℃ | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 |

| Lifespan | year | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 |