Product Video

This video gives you a quick look at all our aeration solutions from fine bubble plate diffusers to disc diffusers. Learn how they work together for efficient wastewater treatment.

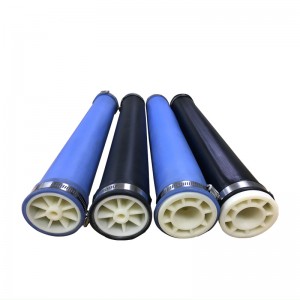

Product Features

1. Compatible with membrane replacements of other diffuser brands in any membrane type and size.

2. Easy to install or retrofit into piping systems of various types and dimensions.

3. Made from high-quality materials to ensure a long service life — up to 10 years under proper operation.

4. Saves space and energy, helping to reduce labor and operational costs.

5. A quick and effective upgrade for outdated and inefficient aeration technologies.

Typical applications

✅ Fish ponds and other aquaculture

✅ Deep aeration basins

✅ Excreta and animal wastewater treatment plants

✅ Denitrification and dephosphorization aerobic processes

✅ High-concentration wastewater aeration basins and regulating ponds

✅ SBR, MBBR reaction basins, contact oxidation ponds, and activated sludge aeration basins in sewage treatment plants