Product Video

Watch how our Static Screen works for effective solid-liquid separation.

Applications

The Static Screen is widely used in various industries for wastewater pretreatment and resource recovery:

-

1. Papermaking, pulp & fiber recovery — recycling fibers and removing solids.

-

2. Slaughterhouses, tanneries — removing solids like fur, grease, pouches, and waste.

-

3. Food & beverage processing — treating wastewater in sugar, wine, starch, beer, and malt production by removing plant fibers, hulls, scales, etc.

-

4. Municipal sewage & small water supply — pretreatment for domestic or community wastewater.

-

5. River dredging & sludge treatment — solid-liquid separation in environmental projects.

-

6. Textile, petrochemical, printing & dyeing — recovery and pretreatment to remove suspended solids.

Key Features

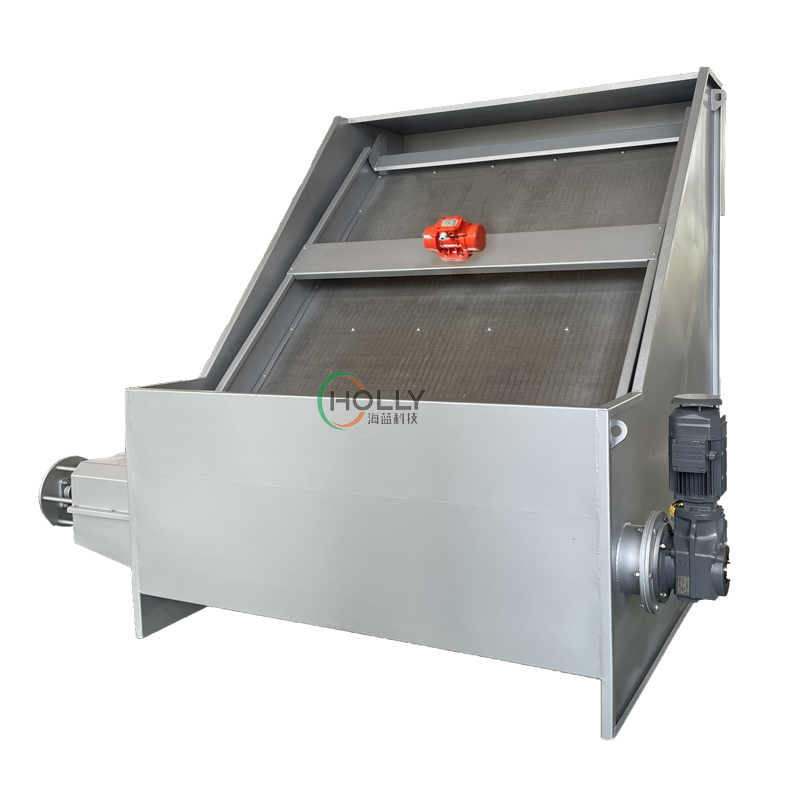

✅ High-Quality Screen Plates — Made from seam-welded stainless steel with high mechanical strength, non-deforming and crack-resistant.

✅ Energy-Saving Operation — Utilizes gravity flow, requiring no power consumption.

✅ Low Maintenance — Periodic manual flushing keeps screen gaps clear and efficient.

✅ Model Selection — The unit does not tolerate shock loads; always select a model with capacity greater than the peak flow rate.

Working Principle

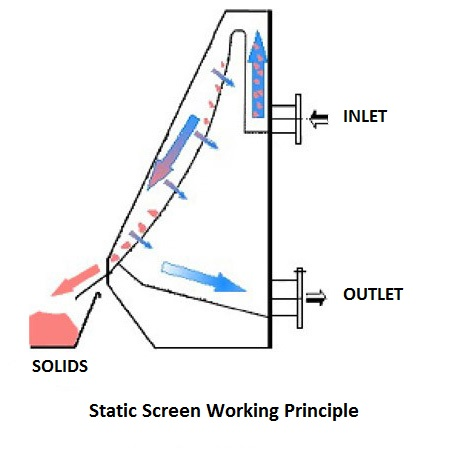

The Static Screen’s core component is an arc-shaped or flat wedge wire screen surface made of stainless steel rods. Wastewater flows evenly over the inclined screen through an overflow weir. Thanks to the smooth surface and wider gaps on the back, drainage is fast and clogging is minimized. Solids are retained and pushed downwards by hydraulic force for discharge, while clean water passes through, achieving reliable solid-liquid separation.

Typical Industries

-

1. Paper mills — fiber recovery, suspended solids removal.

-

2. Tanneries — removal of fur, grease, and other residues.

-

3. Slaughterhouses — solids such as pouches, fur, grease, and waste.

-

4. Municipal wastewater — domestic sewage pretreatment.

-

5. Starch, alcohol, sugar, beer, and malt factories — removal of plant shells, fiber, malt skins.

-

6. Pharmaceutical & food processing — separation of various waste residues.

-

7. Poultry & livestock farms — removal of animal hair, manure, and debris.

-

8. Fish & meat processing — offal, scales, minced meat, grease removal.

-

9. Other applications — textile mills, chemical plants, plastic factories, large workshops, hotels, and residential communities.

Technical Parameters

| Model & Description |

HLSS-500 |

HLSS-1000 |

HLSS-1200 |

HLSS-1500 |

HLSS-1800 |

HLSS-2000 |

HLSS-2400 |

|

| Screen Width (mm) |

500 |

1000 |

1200 |

1500 |

1800 |

2000 |

2400 |

|

| Screen Length (mm) |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

|

| Device Width (mm) |

640 |

1140 |

1340 |

1640 |

1940 |

2140 |

2540 |

|

| Inlet DN |

80 |

100 |

150 |

150 |

200 |

200 |

250 |

|

| Outlet DN |

100 |

125 |

200 |

200 |

250 |

250 |

300 |

|

| Capacity @0.3mm Slot (m³/h) | Poultry |

7.5 |

12 |

15 |

18 |

22.5 |

27 |

30 |

| Capacity @0.5mm Slot (m³/h) | Poultry |

12.5 |

20 |

25 |

30 |

37.5 |

45 |

50 |

| Muncipal |

35 |

56 |

70 |

84 |

105 |

126 |

140 |

|

| Capacity @1.0mm Slot (m³/h) | Poultry |

25 |

40 |

50 |

60 |

75 |

90 |

100 |

| Muncipal |

60 |

96 |

120 |

144 |

180 |

216 |

240 |

|

| Capacity @2.0mm Slot (m³/h) | Muncipal |

90 |

144 |

180 |

216 |

270 |

324 |

360 |