Working Principle

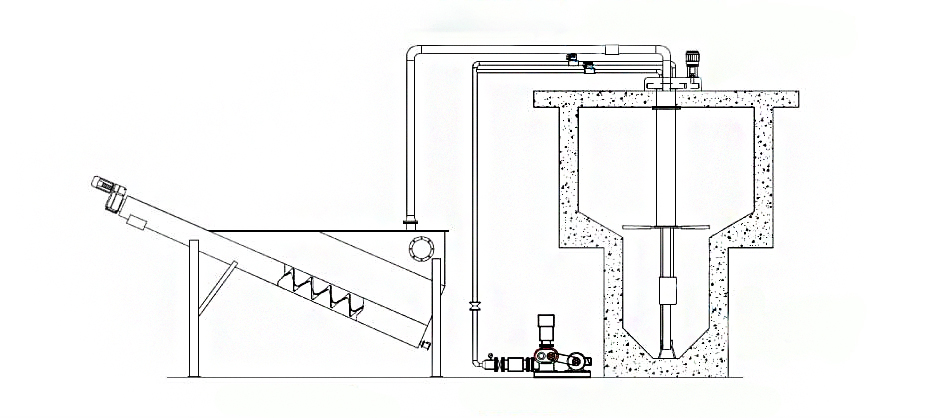

Raw sewage enters tangentially, initiating a vortex motion. With the aid of an impeller, a controlled swirling flow is generated to promote fluidization. Sand particles, often mixed with organic matter, are scrubbed clean through mutual friction and settle to the center of the hopper under gravity and vortex resistance.

The separated organic materials are carried upward along the axial flow. The collected grit is then lifted via an air-lift or pump system and directed to a grit separator. After separation, the clean grit is discharged into a grit bin (cylinder), while the remaining sewage returns to the bar screen chamber.

Product Features

1. Compact footprint and space-saving design, with minimal environmental impact and good surrounding conditions.

2. Stable grit removal performance under varying flow rates. The system ensures efficient sand-water separation, and the extracted sand has low moisture content for easy transportation.

3. Fully automated operation with a PLC control system that manages sand washing and discharge cycles reliably and efficiently.

Technical parameters

| Model | Capacity | Device | Pool Diameter | Extraction Amount | Blower | ||

| Impeller speed | Power | Volume | Power | ||||

| XLCS-180 | 180 | 12-20r/min | 1.1kw | 1830 | 1-1.2 | 1.43 | 1.5 |

| XLCS-360 | 360 | 2130 | 1.2-1.8 | 1.79 | 2.2 | ||

| XLCS-720 | 720 | 2430 | 1.8-3 | 1.75 | |||

| XLCS-1080 | 1080 | 3050 | 3.0-5.0 | ||||

| XLCS-1980 | 1980 | 1.5kw | 3650 | 5-9.8 | 2.03 | 3 | |

| XLCS-3170 | 3170 | 4870 | 9.8-15 | 1.98 | 4 | ||

| XLCS-4750 | 4750 | 5480 | 15-22 | ||||

| XLCS-6300 | 6300 | 5800 | 22-28 | 2.01 | |||

| XLCS-7200 | 7200 | 6100 | 28-30 | ||||

Application Fields

Textile Industry Wastewater

Industrial Wastewater

Domestic Sewage

Restaurant and Catering Wastewater

Municipal Wastewater