Product Description

UV sterilization is an advanced and eco-friendly physical disinfection process that efficiently kills microorganisms such as bacteria, viruses, algae, spores, and other pathogens. It produces no toxic or harmful by-products and is effective in eliminating both organic and inorganic pollutants, including residual chlorine. UV technology is increasingly favored for treating emerging contaminants such as chloramine, ozone, and TOC. It is widely applied in diverse water treatment settings as a standalone or complementary method to chemical disinfection.

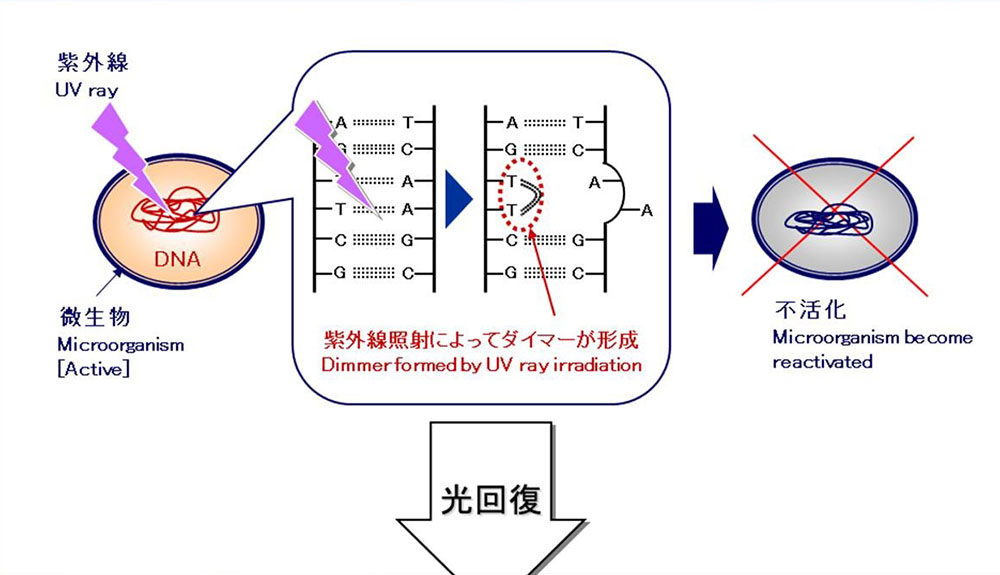

Working Principle

UV disinfection operates in the 225–275 nm wavelength range, with peak effectiveness at 254 nm. This UV spectrum disrupts the DNA and RNA of microorganisms, preventing protein synthesis and cell replication, ultimately rendering them inactive and unable to reproduce.

This advanced water disinfection technology has been widely adopted since the late 1990s after decades of research and development. UV sterilization is now considered one of the most efficient and cost-effective disinfection methods globally. It is suitable for fresh water, seawater, industrial wastewater, and high-risk pathogenic water sources.

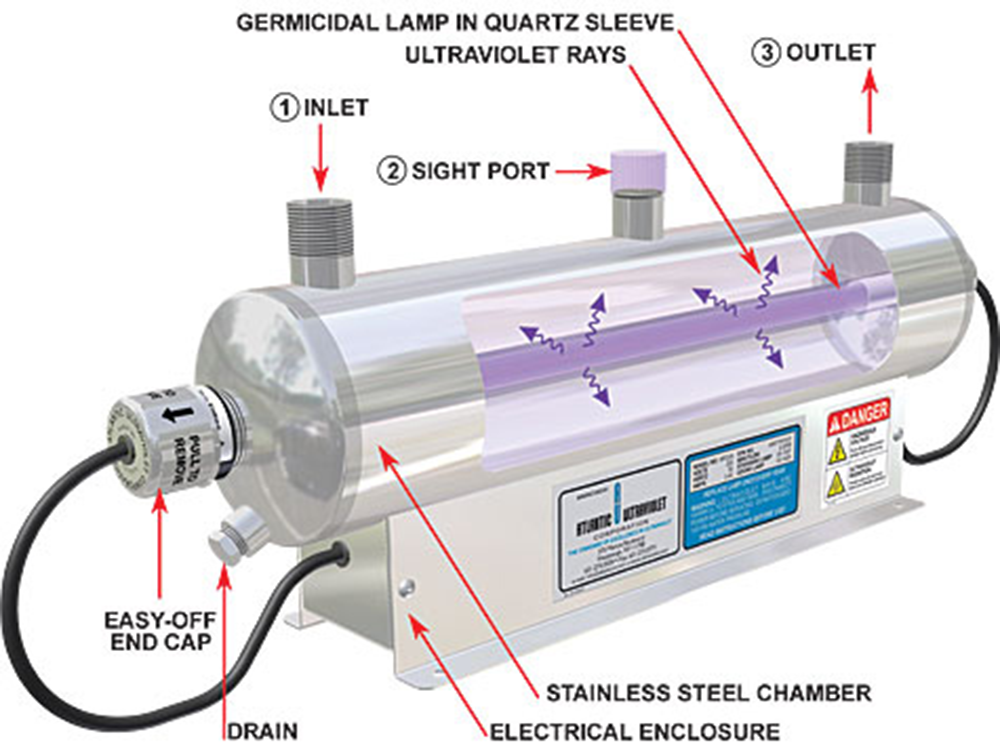

General structure

Refer to the image for a visual overview of the product's structure. The equipment is designed for durability and ease of integration into various systems.

Product Paramenters

|

Model |

Inlet/Outlet |

Diameter (mm) |

Length (mm) |

Water Flow T/H |

Numbers |

Total Power (W) |

|

XMQ172W-L1 |

DN65 |

133 |

950 |

1-5 |

1 |

172 |

|

XMQ172W-L2 |

DN80 |

159 |

950 |

6-10 |

2 |

344 |

|

XMQ172W-L3 |

DN100 |

159 |

950 |

11-15 |

3 |

516 |

|

XMQ172W-L4 |

DN100 |

159 |

950 |

16-20 |

4 |

688 |

|

XMQ172W--L5 |

DN125 |

219 |

950 |

21-25 |

5 |

860 |

|

XMQ172W-L6 |

DN125 |

219 |

950 |

26-30 |

6 |

1032 |

|

XMQ172W-L7 |

DN150 |

273 |

950 |

31-35 |

7 |

1204 |

|

XMQ172W-L8 |

DN150 |

273 |

950 |

36-40 |

8 |

1376 |

|

XMQ320W-L5 |

DN150 |

219 |

1800 |

50 |

5 |

1600 |

|

XMQ320W-L6 |

DN150 |

219 |

1800 |

60 |

6 |

1920 |

|

XMQ320W-L7 |

DN200 |

273 |

1800 |

70 |

7 |

2240 |

|

XMQ320W-L8 |

DN250 |

273 |

1800 |

80 |

8 |

2560 |

|

Inlet/Outlet Size |

1" to 12" |

|

Water Treatment Capacity |

1–290 T/h |

|

Power Supply |

AC220V ±10V, 50Hz/60Hz |

|

Reactor Material |

304 / 316L Stainless Steel |

|

Max. Working Pressure |

0.8 MPa |

|

Casing Cleaning Device |

Manual cleaning type |

|

Quartz Sleeve Types (QS models) |

57W (417mm), 172W (890mm), 320W (1650mm) |

| Note: Flow rates are based on 30 mJ/cm² UV dose at 95% UV transmittance (UVT) at end of lamp life. Achieves 4-log (99.99%) reduction in bacteria, viruses, and protozoan cysts. | |

Features

1. Compact design with external control cabinet; the UV chamber and electrical components can be installed separately for space efficiency.

2. Durable construction using 304/316/316L stainless steel (optional), polished inside and out for excellent corrosion and deformation resistance.

3. High-pressure tolerance up to 0.6 MPa, protection grade IP68, and complete UV sealing for safe, leak-free operation.

4. Equipped with high-transmittance quartz sleeves and imported Toshiba UV lamps from Japan; lamp life exceeds 12,000 hours with consistent low UV-C attenuation.

5. Optional online monitoring and remote control system for real-time performance tracking.

6. Optional manual or automatic cleaning system to maintain optimal UV efficiency.

Application

✅ Sewage Disinfection: Municipal, hospital, industrial wastewater, and oilfield reinjection.

✅ Water Supply Disinfection: Tap water, groundwater, river/lake water, and surface water.

✅ Pure Water Disinfection: For use in food, beverage, electronics, pharmaceutical, cosmetic, and injection water applications.

✅ Aquaculture & Farming: Shellfish purification, aquaculture, livestock and poultry breeding, and irrigation in eco-agriculture.

✅ Circulating Water Disinfection: Swimming pools, landscape water, and industrial cooling water.

✅ Other Uses: Reclaimed water, algae control, secondary project water, and household/villa water treatment.