Key Advantages

-

1. No central shaft: minimizes material blockage and entanglement

-

2. Flexible spiral: adapts to a variety of material types and installation angles

-

3. Fully enclosed structure: reduces odors and prevents environmental contamination

-

4. Easy maintenance and long service life

Applications

Shaftless screw conveyors are ideal for handling difficult or sticky materials that may cause clogging in traditional systems. Typical applications include:

-

✅ Wastewater treatment: sludge, screenings

-

✅ Food processing: leftover organic matter, fibrous waste

-

✅ Pulp & paper industry: pulp residue

-

✅ Municipal waste: hospital waste, compost, solid waste

-

✅ Industrial waste: metal shavings, plastic scraps, etc.

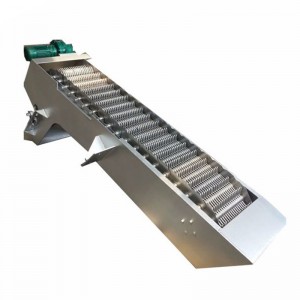

Working Principle & Structure

The system consists of a shaftless spiral screw rotating within a U-shaped trough, with an inlet hopper and an outlet spout. As the spiral rotates, it pushes materials from the inlet toward the discharge point. The enclosed trough ensures clean and efficient material handling while reducing wear and tear on the equipment.

Inclined Mounting

Technical Parameters

| Model | HLSC200 | HLSC200 | HLSC320 | HLSC350 | HLSC420 | HLSC500 | |

| Conveying Capacity (m³/h) | 0° | 2 | 3.5 | 9 | 11.5 | 15 | 25 |

| 15° | 1.4 | 2.5 | 6.5 | 7.8 | 11 | 20 | |

| 30° | 0.9 | 1.5 | 4.1 | 5.5 | 7.5 | 15 | |

| Max Conveying Length (m) | 10 | 15 | 20 | 20 | 20 | 25 | |

| Body Material | SS304 | ||||||

Model Code Explanation

Each shaftless screw conveyor is identified by a specific model code based on its configuration. The model number reflects the trough width, conveying length, and installation angle.

Model Format: HLSC–□×□×□

-

✔️ Shaftless Screw Conveyor (HLSC)

-

✔️ U-shaped Trough Width (mm)

-

✔️ Conveying Length (m)

-

✔️ Conveying Angle (°)

Refer to the diagram below for detailed parameter structure: