Key Advantages

-

✅ Standardized and mass-produced, ensuring stable quality and reliable performance.

-

✅ Uses Dutch DSM resin for high structural integrity, chemical resistance, and durability for underground use (up to 30 years).

-

✅ Features a patented water distribution system to eliminate dead zones and ensure optimal flow and volume.

-

✅ Reinforced with a patented corrugated surface design for high strength, even in frozen soil conditions.

-

✅ Incorporates patented filler and bio-media combinations for rapid microbial colonization and effective treatment.

-

✅ Equipped with denitrifying and phosphorus-removing bacteria, allowing for fast startup, resistance to shock loads, and reduced sludge generation.

-

✅ Easy to install, operate, and maintain, with optional remote monitoring and control.

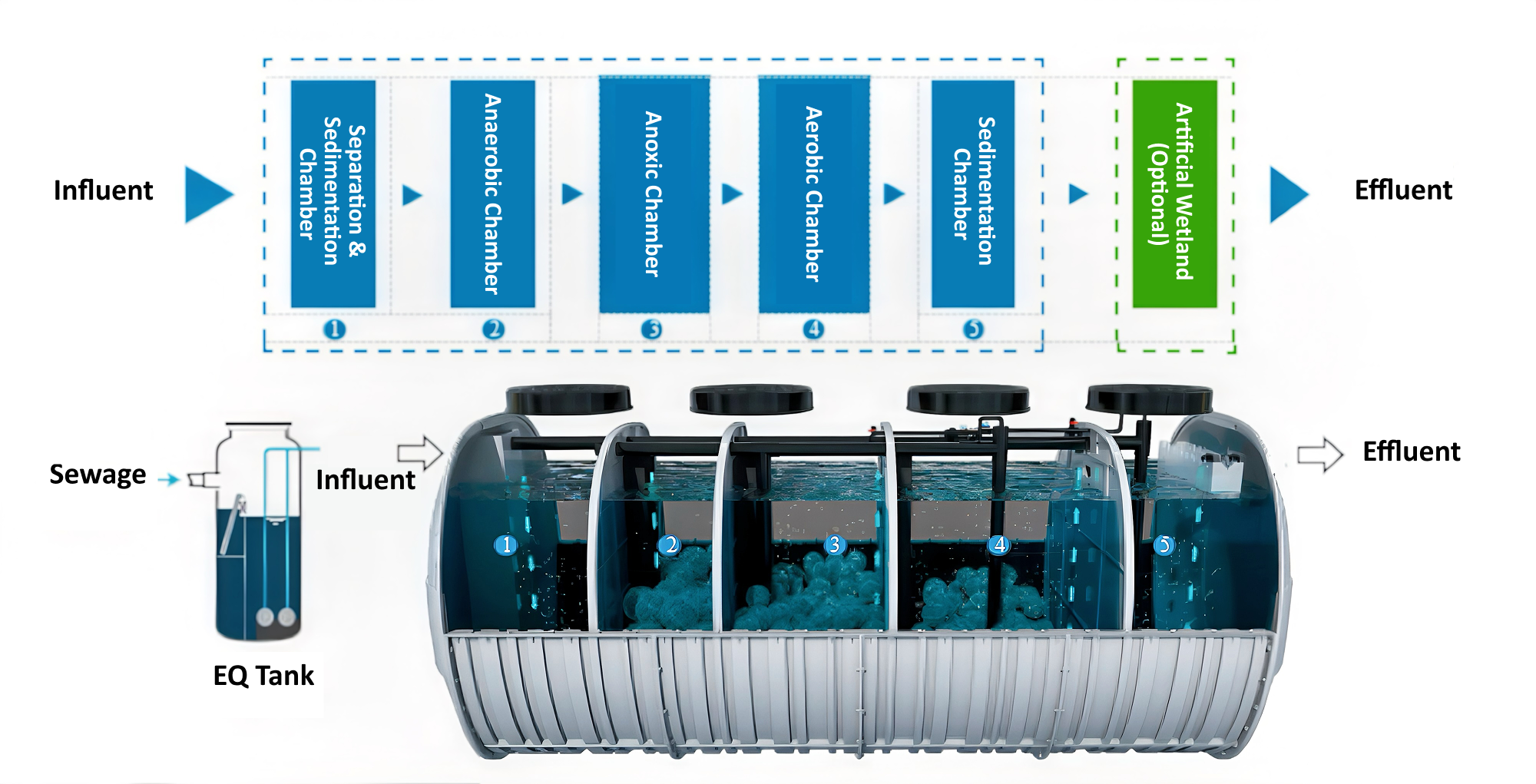

Process Flow

This pre-packaged wastewater treatment system is engineered for treating sewage from kitchens, toilets, and laundry facilities. Kitchen wastewater is pre-treated with a grease trap, while toilet flushing sewage must first pass through a septic tank. The collected wastewater flows into the Johkasou system, where it undergoes biological treatment through anaerobic, anoxic, and aerobic phases. Pollutants are significantly reduced before the water is discharged, and excess sludge is periodically removed using a suction truck every 3–6 months.

Specifications

| Model | Capacity(m³/d) | Dimensions(mm) | Manhole (mm) | Blower Power(W) | Main Material |

| HLSTP-0.5 | 0.5 | 1950*1170*1080 | Φ400*2 | 38 | SMC |

| HLSTP -1 | 1 | 2400*1300*1400 | Φ400*2 | 45 | SMC |

| HLSTP-2 | 2 | 2130*1150*1650 | Φ630*2 | 55 | SMC |

| HLSTP-5 | 5 | 2420*2010*2000 | Φ630*2 | 110 | SMC |

| HLSTP-8 | 8 | 3420*2010*2000 | Φ630*3 | 110 | SMC |

| HLSTP-10 | 10 | 4420*2010*2000 | Φ630*4 | 170 | SMC |

| HLSTP-15 | 15 | 5420*2010*2000 | Φ630*5 | 220 | SMC |

| HLSTP-20 | 20 | 7420*2010*2000 | Φ630*6 | 350 | SMC |

| HLSTP-25 | 25 | 8420*2010*2000 | Φ630*6 | 470 | SMC |

| HLSTP-30 | 30 | 10420*2010*2000 | Φ630*6 | 470 | SMC |

| HLSTP-40 | 40 | Φ2500*8500 | Φ630*6 | 750 | GRP |

| HLSTP-50 | 50 | Φ2500*10500 | Φ630*6 | 1500 | GRP |

| HLSTP-60 | 60 | ¢2500*12500 | Φ630*6 | 1500 | GRP |

| HLSTP-70 | 70 | ¢3000*10000 | Φ630*6 | 1500 | GRP |

| HLSTP-80 | 80 | ¢3000×11500 | Φ630*6 | 2200 | GRP |

| HLSTP-90 | 90 | ¢3000×13000 | Φ630*6 | 2200 | GRP |

| HLSTP-100 | 100 | ¢3000×13500 | Φ630*6 | 2200 | GRP |

Applications

Construction site domestic sewage treatment

Rural or suburban point-source wastewater treatment

Scenic spot and tourist area sewage treatment

Sewage treatment in ecological protection and drinking water source areas

Hospital wastewater treatment

Highway service station or remote site sewage management

Ideal for use in:

-

Construction site domestic sewage treatment

-

Rural or suburban point-source wastewater treatment

-

Scenic spot and tourist area sewage treatment

-

Sewage treatment in ecological protection and drinking water source areas

-

Hospital wastewater treatment

-

Highway service station or remote site sewage management

Case Studies