Choosing the correct screw press sludge dewatering machine starts with one key number:

Dry solids capacity (kgDS/h).

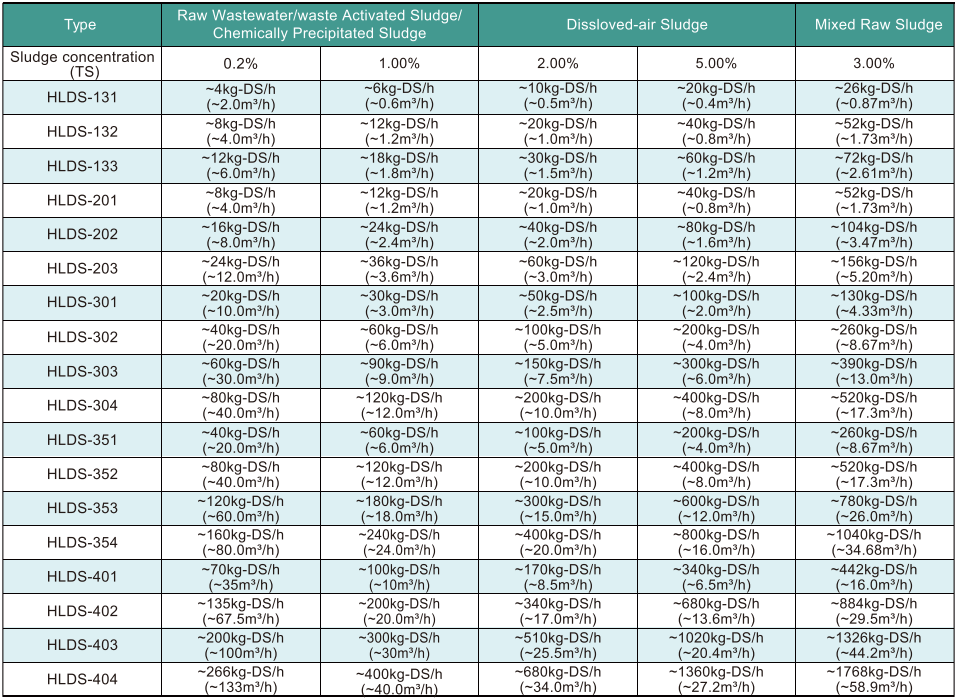

All screw press models are selected based on this parameter. Once you know your required kgDS/h, the right model can be determined quickly.

Simple Selection Formula

Daily wastewater flow (m³/day) × sludge yield (kgDS/m³) ÷ operating hours (h/day) = required kgDS/h

Example

10,000 m³/day × 0.8 kgDS/m³ ÷ 20 h/day = 400 kgDS/h

In this case, select a screw press with capacity slightly above 400 kgDS/h.

We recommend reserving 20–30% extra capacity for stable operation.

What Information Do We Need?

You can send us any of the following:

①Required dry solids capacity (kgDS/h)

②Sludge flow rate and concentration

③Existing sludge cake output (T/day)

④Daily wastewater treatment capacity

Our engineers will calculate the correct screw press sludge dewatering equipment model for you.

Why Proper Screw Press Selection Matters

Correct sizing ensures:

①Stable sludge dewatering performance

②Lower polymer consumption

③Reduced energy cost

④Longer equipment lifespan

⑤Avoidance of overload or overspending

Undersized machines cause operational problems.

Oversized machines increase investment cost.

Proper selection protects your project.

Get Professional Selection Support

If you are planning a new wastewater treatment plant or replacing a filter press or centrifuge, we can provide fast and accurate screw press selection support.

Send us your project data today and receive:

√Recommended screw press model

√Capacity confirmation (kgDS/h)

√Technical proposal

√Quotation

Holly Group will help you choose the most suitable multi disc screw press sludge dewatering system for your application.

Email: lisa@holly-tech.net.cn

Tel: 86-15995395879

Website: www.hollyep.com

Post time: Feb-11-2026