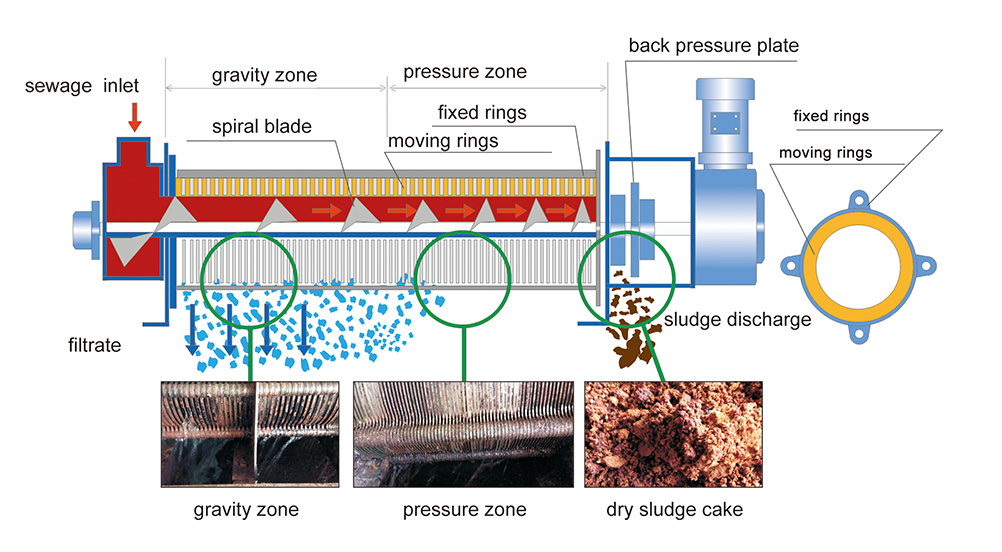

Working Principle:

Conditioned sludge is fed into the dewatering zone from the flocculation tank. As it progresses through the narrowing gaps formed by the screw shaft and moving rings, pressure builds up and water is gradually squeezed out.

Separated water flows through the gaps between moving and fixed rings, which are automatically cleaned by the motion of the rings themselves—effectively preventing clogging and ensuring continuous operation. The compressed sludge cake is finally discharged from the end.

Key Features:

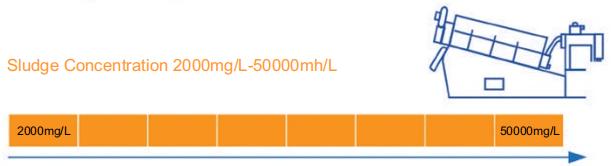

Pre-concentration for low-concentration sludge

Equipped with an exclusive spiral plate, the machine performs efficient pre-concentration, making it especially suitable for treating low-concentration sludge. By replacing traditional gravity-type dehydrators and integrating flocculation and concentration processes, it simplifies sludge treatment. The solenoid control valve further enhances slurry concentration for improved dewatering performance.

1. Clog-Free Design with Self-Cleaning Rings

The HLDS uses moving and fixed rings instead of filter cloths, eliminating clogging issues and reducing maintenance needs. It is especially suitable for oily and low-concentration sludge, and requires no high-pressure cleaning, minimizing secondary pollution.

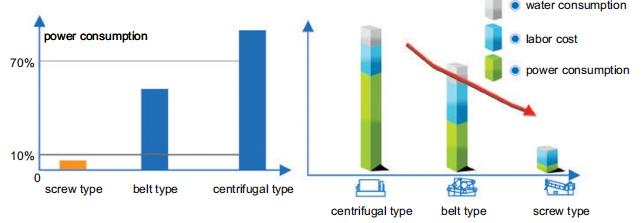

2. Low-Speed, Energy-Efficient Operation

With a rotation speed much lower than that of belt or centrifugal systems, the HLDS screw press reduces energy usage by up to 87.5% compared to belt presses and 95% compared to centrifuges. It also produces less noise during operation.

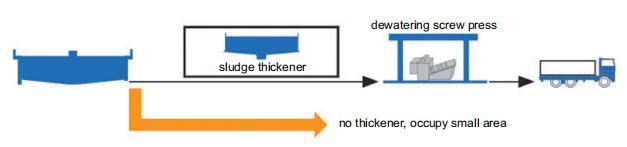

3. Reduced Infrastructure & Operating Costs

The screw sludge dewatering machine can treat sludge directly from aeration and sedimentation tanks, eliminating the need for thickening tanks and reducing phosphorus release. It requires less floor space, leading to lower capital investment in wastewater treatment facilities.

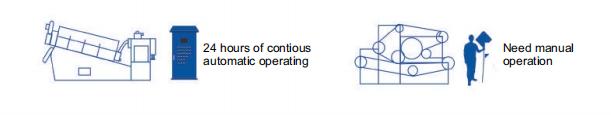

4. Automated Control & Simple Operation

Integrated with a PLC-based electric control cabinet, the system supports fully automated operation. The absence of clog-prone components ensures stable, low-maintenance performance—ideal for facilities requiring 24/7 unattended operation.

Applications:

The dewatering screw press is highly versatile and applicable to a wide range of sludge types and industries:

- ✅ Municipal wastewater treatment

- ✅ Petrochemical & chemical industries

- ✅ Pulp & paper mills

- ✅ Pharmaceutical and dyeing plants

- ✅ Meat & dairy processing

- ✅ Mining wastewater

- ✅ Printing & painting industries

- ✅ Septic tank sludge

- ✅ Palm oil and dairy farm waste

Whether you're managing activated sludge, DAF sludge, mixed sludge, or chemically precipitated sludge, this screw press dewatering machine ensures superior efficiency and return on investment.

Technical Parameters:

| Type | Raw Wastewater / Waste Activated Sludge / Chemically Precipitated Sludge | Dissolved Air Sludge | Mixed Raw Sludge | ||

| Sludge Concentration (TS) | 0.20% | 1.00% | 2.00% | 5.00% | 3.00% |

| HLDS-131 | ~4kg-DS/h(~2.0m³/h) | ~6kg-DS/h(~0.6m³/h) | ~10kg-DS/h(~0.5m³/h) | ~20kg-DS/h(~0.4m³/h) | ~26kg-DS/h(~0.87m³/h) |

| HLDS-132 | ~8kg-DS/h(~4.0m³/h) | ~12kg-DS/h(~1.2m³/h) | ~20kg-DS/h(~1.0m³/h) | ~40kg-DS/h(~0.5m³/h) | ~52kg-DS/h(~1.73m³/h) |

| HLDS-133 | ~12kg-DS/h(~6.0m³/h) | ~18kg-DS/h(~1.8m³/h) | ~30kg-DS/h(~1.5m³/h) | ~60kg-DS/h(~1.2m³/h) | ~72kg-DS/h(~2.61m³/h) |

| HLDS-201 | ~8kg-DS/h(~4.0m³/h) | ~12kg-DS/h(~1.2m³/h) | ~20kg-DS/h(~1.0m³/h) | ~40kg-DS/h(~0.8m³/h) | ~52kg-DS/h(~1.73m³/h) |

| HLDS-202 | ~16kg-DS/h(~8.0m³/h) | ~24kg-DS/h(~2.4m³/h) | ~40kg-DS/h(~2.0m³/h) | ~80kg-DS/h(~1.6m³/h) | ~104kg-DS/h(~3.47m³/h) |

| HLDS-203 | ~24kg-DS/h(~12.0m³/h) | ~36kg-DS/h(~3.6m³/h) | ~60kg-DS/h(~3.0m³/h) | ~120kg-DS/h(~2.4m³/h) | ~156kg-DS/h(~5.20m³/h) |

| HLDS-301 | ~20kg-DS/h(~10.0m³/h) | ~30kg-DS/h(~3.0m³/h) | ~50kg-DS/h(~2.5m³/h) | ~100kg-DS/h(~2.0m³/h) | ~130kg-DS/h(~4.33m³/h) |

| HLDS-302 | ~40kg-DS/h(~20.0m³/h) | ~60kg-DS/h(~6.0m³/h) | ~100kg-DS/h(~5.0m³/h) | ~200kg-DS/h(~4.0m³/h) | ~260kg-DS/h(~8.67m³/h) |

| HLDS-303 | ~60kg-DS/h(~30.0m³/h) | ~90kg-DS/h(~9.0m³/h) | ~150kg-DS/h(~7.5m³/h) | ~300kg-DS/h(~6.0m³/h) | ~390kg-DS/h(~13.0m³/h) |

| HLDS-304 | ~80kg-DS/h(~40.0m³/h) | ~120kg-DS/h(~12.0m³/h) | ~200kg-DS/h(~10.0m³/h) | ~400kg-DS/h(~8.0m³/h) | ~520kg-DS/h(~17.3m³/h) |

| HLDS-351 | ~40kg-DS/h(~20.0m³/h) | ~60kg-DS/h(~6.0m³/h) | ~100kg-DS/h(~5.0m³/h) | ~200kg-DS/h(~4.0m³/h) | ~260kg-DS/h(~8.67m³/h) |

| HLDS-352 | ~80kg-DS/h(~40.0m³/h) | ~120kg-DS/h(~12.0m³/h) | ~200kg-DS/h(~10.0m³/h) | ~400kg-DS/h(~8.0m³/h) | ~520kg-DS/h(~17.3m³/h) |

| HLDS-353 | ~120kg-DS/h(~60.0m³/h) | ~180kg-DS/h(~18.0m³/h) | ~300kg-DS/h(~15.0m³/h) | ~600kg-DS/h(~12.0m³/h) | ~780kg-DS/h(~26.0m³/h) |

| HLDS-354 | ~160kg-DS/h(~80.0m³/h) | ~240kg-DS/h(~24.0m³/h) | ~400kg-DS/h(~20.0m³/h) | ~800kg-DS/h(~16.0m³/h) | ~1040kg-DS/h(~34.68m³/h) |

| HLDS-401 | ~70kg-DS/h(~35.0m³/h) | ~100kg-DS/h(~10m³/h) | ~170kg-DS/h(~8.5m³/h) | ~340kg-DS/h(~6.5m³/h) | ~442kg-DS/h(~16.0m³/h) |

| HLDS-402 | ~135kg-DS/h(~67.5m³/h) | ~200kg-DS/h(~20.0m³/h) | ~340kg-DS/h(~17.0m³/h) | ~680kg-DS/h(~13.6m³/h) | ~884kg-DS/h(~29.5m³/h) |

| HLDS-403 | ~200kg-DS/h(~100m³/h) | ~300kg-DS/h(~30.0m³/h) | ~510kg-DS/h(~25.5m³/h) | ~1020kg-DS/h(~20.4m³/h) | ~1326kg-DS/h(~44.2m³/h) |

| HLDS-404 | ~266kg-DS/h(~133m³/h) | ~400kg-DS/h(~40.0m³/h) | ~680kg-DS/h(~34.0m³/h) | ~1360kg-DS/h(~27.2m³/h) | ~1768kg-DS/h(~58.9m³/h) |

| Type | Discharge Height | Dimensions | Weight (kg) | Power (kW) | Washing Water (L/h) | |||

| L(mm) | W(mm) | H(mm) | Empty | Operating | ||||

| HLDS-131 | 250 | 1860 | 750 | 1080 | 180 | 300 | 0.2 | 24 |

| HLDS-132 | 250 | 1960 | 870 | 1080 | 250 | 425 | 0.3 | 48 |

| HLDS-133 | 250 | 1960 | 920 | 1080 | 330 | 580 | 0.4 | 72 |

| HLDS-201 | 350 | 2510 | 900 | 1300 | 320 | 470 | 1.1 | 32 |

| HLDS-202 | 350 | 2560 | 1050 | 1300 | 470 | 730 | 1.65 | 64 |

| HLDS-203 | 350 | 2610 | 1285 | 1300 | 650 | 1100 | 2.2 | 96 |

| HLDS-301 | 495 | 3330 | 1005 | 1760 | 850 | 1320 | 1.3 | 40 |

| HLDS-302 | 495 | 3530 | 1290 | 1760 | 1300 | 2130 | 2.05 | 80 |

| HLDS-303 | 495 | 3680 | 1620 | 1760 | 1750 | 2880 | 2.8 | 120 |

| HLDS-304 | 495 | 3830 | 2010 | 1760 | 2300 | 3850 | 3.55 | 160 |

| HLDS-351 | 585 | 4005 | 1100 | 2130 | 1100 | 1900 | 1.3 | 72 |

| HLDS-352 | 585 | 4390 | 1650 | 2130 | 1900 | 3200 | 2.05 | 144 |

| HLDS-353 | 585 | 4520 | 1980 | 2130 | 2550 | 4600 | 2.8 | 216 |

| HLDS-354 | 585 | 4750 | 2715 | 2130 | 3200 | 6100 | 3.55 | 288 |

| HLDS-401 | 759 | 4680 | 1110 | 2100 | 1600 | 3400 | 1.65 | 80 |

| HLDS-402 | 759 | 4960 | 1760 | 2100 | 2450 | 5200 | 2.75 | 160 |

| HLDS-403 | 759 | 5010 | 2585 | 2100 | 3350 | 7050 | 3.85 | 240 |

| HLDS-404 | 759 | 5160 | 3160 | 2100 | 4350 | 9660 | 4.95 | 320 |