Hot-selling Sludge Dewatering Technologies - Multi-disc Sludge Dewatering Screw Press Machine – Holly Detail:

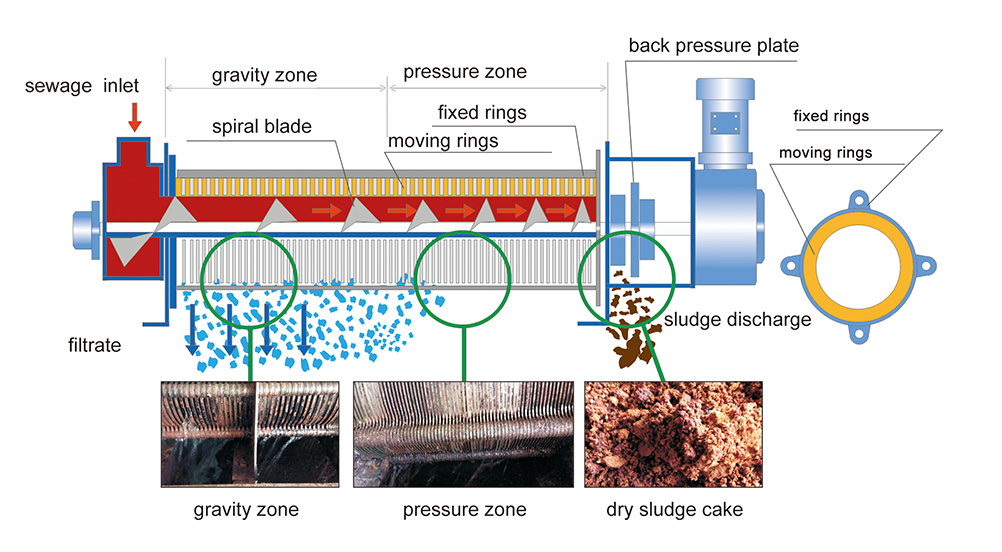

Working Principle:

The conditioned sludge flows into the filter zones from the flocculation tank and is pushed forward to the discharging end. With the gaps between the thread of the shaft is getting even narrower the pressure on the sludge is getting higher and higher. Than the water is separated from the sludge and flows out from the gaps between the moving rings and fixed rings. The movement of the moving rings will clean the gaps between moving and fixed rings and prevent the machine from blockage ..

The filtered sludge cakes will be pushed forward by the finally discharged from the end

Features:

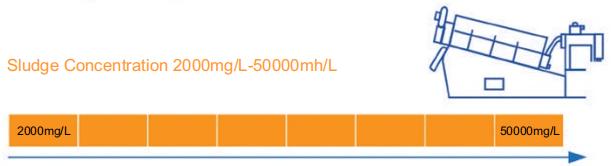

Configurating exclusive spiral plate for pre-concentration and better for treating low concentration sludge.

Replacing gravity type dehydrator to realize efficient concentration of sludge.

Flocculation and concentration operating together makes dewatering easy.

Optimize concentration of slurry for dewatering with solenoid control valve.

1. Rings substitute filter cloth, self cleaning, no clogging, easy treatment .

The dewatering screw press allows continuous operation with no clogging due to the moving of the fixed rings and moving rings cleaning it self. Therefore, it’s especially good at oily sludge with excellent performance. Moreover, it doesn’t need additional water for high-pressure cleaning so that no small or secondary pollution will be produced.

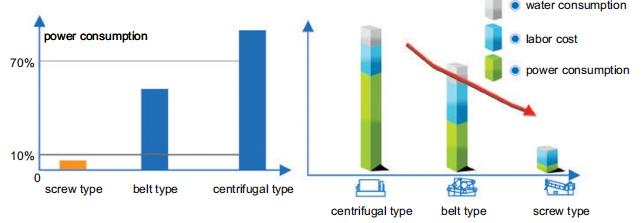

2. Low speed operation, low noise, low energy consumption, only 1/8 of the belt type, 1/20 of the centrifuge.

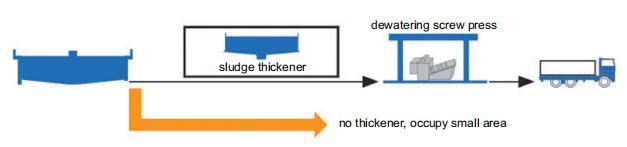

3. Reduce the cost of infrastructure investment, improved the result of treatment

The dewatering screw press can directly treat the sludge from the aeration tank and the sedimentation tank

so that the sludge thickening tank is not needed any more.

Therefore, the construction cost can be greatly reduced and well avoided the phosphorus releasing problem.

Saving the cost of sludge thickening tank and other equipments investment.

Occupy smaller area, reduce construction investment for dewatering.

4. Fully automatic control, easy operation and maintenance.

The dewatering screw press has no easy-blocking components like filter cloth or filtration pore inside.

Its operation is safe and easy. It also can be set to operate automatically via the elec-control cabinet.

Applications:

The Sludge Dewatering Screw Press can be widely used for various wastewater treatment systems such as municipal, petrochemical, chemical fiber, paper making, pharmaceutical, leather and other industrial water treatment system. Also it can be used for Dairy Farm Manure Treatment, Palm Oil Sludge, Septic Sludge, etc. The practical operation shows that Dewatering Screw Press can bring considerable economic and social benefits for users.

Technical Parameters

| Type | Raw wastewater/Waste actived sludge/Chemically precipitated sludge | Dissolved-air sludge | Mixed raw sludge | ||

| Sludge concentration(TS) | 0.20% | 1.00% | 2.00% | 5.00% | 3.00% |

| HLDS-131 | ~4kg-DS/h(~2.0m³/h) | ~6kg-DS/h(~0.6m³/h) | ~10kg-DS/h(~0.5m³/h) | ~20kg-DS/h(~0.4m³/h) | ~26kg-DS/h(~0.87m³/h) |

| HLDS-132 | ~8kg-DS/h(~4.0m³/h) | ~12kg-DS/h(~1.2m³/h) | ~20kg-DS/h(~1.0m³/h) | ~40kg-DS/h(~0.5m³/h) | ~52kg-DS/h(~1.73m³/h) |

| HLDS-133 | ~12kg-DS/h(~6.0m³/h) | ~18kg-DS/h(~1.8m³/h) | ~30kg-DS/h(~1.5m³/h) | ~60kg-DS/h(~1.2m³/h) | ~72kg-DS/h(~2.61m³/h) |

| HLDS-201 | ~8kg-DS/h(~4.0m³/h) | ~12kg-DS/h(~1.2m³/h) | ~20kg-DS/h(~1.0m³/h) | ~40kg-DS/h(~0.8m³/h) | ~52kg-DS/h(~1.73m³/h) |

| HLDS-202 | ~16kg-DS/h(~8.0m³/h) | ~24kg-DS/h(~2.4m³/h) | ~40kg-DS/h(~2.0m³/h) | ~80kg-DS/h(~1.6m³/h) | ~104kg-DS/h(~3.47m³/h) |

| HLDS-203 | ~24kg-DS/h(~12.0m³/h) | ~36kg-DS/h(~3.6m³/h) | ~60kg-DS/h(~3.0m³/h) | ~120kg-DS/h(~2.4m³/h) | ~156kg-DS/h(~5.20m³/h) |

| HLDS-301 | ~20kg-DS/h(~10.0m³/h) | ~30kg-DS/h(~3.0m³/h) | ~50kg-DS/h(~2.5m³/h) | ~100kg-DS/h(~2.0m³/h) | ~130kg-DS/h(~4.33m³/h) |

| HLDS-302 | ~40kg-DS/h(~20.0m³/h) | ~60kg-DS/h(~6.0m³/h) | ~100kg-DS/h(~5.0m³/h) | ~200kg-DS/h(~4.0m³/h) | ~260kg-DS/h(~8.67m³/h) |

| HLDS-303 | ~60kg-DS/h(~30.0m³/h) | ~90kg-DS/h(~9.0m³/h) | ~150kg-DS/h(~7.5m³/h) | ~300kg-DS/h(~6.0m³/h) | ~390kg-DS/h(~13.0m³/h) |

| HLDS-304 | ~80kg-DS/h(~40.0m³/h) | ~120kg-DS/h(~12.0m³/h) | ~200kg-DS/h(~10.0m³/h) | ~400kg-DS/h(~8.0m³/h) | ~520kg-DS/h(~17.3m³/h) |

| HLDS-351 | ~40kg-DS/h(~20.0m³/h) | ~60kg-DS/h(~6.0m³/h) | ~100kg-DS/h(~5.0m³/h) | ~200kg-DS/h(~4.0m³/h) | ~260kg-DS/h(~8.67m³/h) |

| HLDS-352 | ~80kg-DS/h(~40.0m³/h) | ~120kg-DS/h(~12.0m³/h) | ~200kg-DS/h(~10.0m³/h) | ~400kg-DS/h(~8.0m³/h) | ~520kg-DS/h(~17.3m³/h) |

| HLDS-353 | ~120kg-DS/h(~60.0m³/h) | ~180kg-DS/h(~18.0m³/h) | ~300kg-DS/h(~15.0m³/h) | ~600kg-DS/h(~12.0m³/h) | ~780kg-DS/h(~26.0m³/h) |

| HLDS-354 | ~160kg-DS/h(~80.0m³/h) | ~240kg-DS/h(~24.0m³/h) | ~400kg-DS/h(~20.0m³/h) | ~800kg-DS/h(~16.0m³/h) | ~1040kg-DS/h(~34.68m³/h) |

| HLDS-401 | ~70kg-DS/h(~35.0m³/h) | ~100kg-DS/h(~10m³/h) | ~170kg-DS/h(~8.5m³/h) | ~340kg-DS/h(~6.5m³/h) | ~442kg-DS/h(~16.0m³/h) |

| HLDS-402 | ~135kg-DS/h(~67.5m³/h) | ~200kg-DS/h(~20.0m³/h) | ~340kg-DS/h(~17.0m³/h) | ~680kg-DS/h(~13.6m³/h) | ~884kg-DS/h(~29.5m³/h) |

| HLDS-403 | ~200kg-DS/h(~100m³/h) | ~300kg-DS/h(~30.0m³/h) | ~510kg-DS/h(~25.5m³/h) | ~1020kg-DS/h(~20.4m³/h) | ~1326kg-DS/h(~44.2m³/h) |

| HLDS-404 | ~266kg-DS/h(~133m³/h) | ~400kg-DS/h(~40.0m³/h) | ~680kg-DS/h(~34.0m³/h) | ~1360kg-DS/h(~27.2m³/h) | ~1768kg-DS/h(~58.9m³/h) |

| Type | Discharge height |

Dimension | Weight(kg) | Total power(kW) |

Washing water consumption(L/h) |

|||

| L(mm) | W(mm) | H(mm) | Empty | Operation | ||||

| HLDS-131 | 250 | 1860 | 750 | 1080 | 180 | 300 | 0.2 | 24 |

| HLDS-132 | 250 | 1960 | 870 | 1080 | 250 | 425 | 0.3 | 48 |

| HLDS-133 | 250 | 1960 | 920 | 1080 | 330 | 580 | 0.4 | 72 |

| HLDS-201 | 350 | 2510 | 900 | 1300 | 320 | 470 | 1.1 | 32 |

| HLDS-202 | 350 | 2560 | 1050 | 1300 | 470 | 730 | 1.65 | 64 |

| HLDS-203 | 350 | 2610 | 1285 | 1300 | 650 | 1100 | 2.2 | 96 |

| HLDS-301 | 495 | 3330 | 1005 | 1760 | 850 | 1320 | 1.3 | 40 |

| HLDS-302 | 495 | 3530 | 1290 | 1760 | 1300 | 2130 | 2.05 | 80 |

| HLDS-303 | 495 | 3680 | 1620 | 1760 | 1750 | 2880 | 2.8 | 120 |

| HLDS-304 | 495 | 3830 | 2010 | 1760 | 2300 | 3850 | 3.55 | 160 |

| HLDS-351 | 585 | 4005 | 1100 | 2130 | 1100 | 1900 | 1.3 | 72 |

| HLDS-352 | 585 | 4390 | 1650 | 2130 | 1900 | 3200 | 2.05 | 144 |

| HLDS-353 | 585 | 4520 | 1980 | 2130 | 2550 | 4600 | 2.8 | 216 |

| HLDS-354 | 585 | 4750 | 2715 | 2130 | 3200 | 6100 | 3.55 | 288 |

| HLDS-401 | 759 | 4680 | 1110 | 2100 | 1600 | 3400 | 1.65 | 80 |

| HLDS-402 | 759 | 4960 | 1760 | 2100 | 2450 | 5200 | 2.75 | 160 |

| HLDS-403 | 759 | 5010 | 2585 | 2100 | 3350 | 7050 | 3.85 | 240 |

| HLDS-404 | 759 | 5160 | 3160 | 2100 | 4350 | 9660 | 4.95 | 320 |

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Hot-selling Sludge Dewatering Technologies - Multi-disc Sludge Dewatering Screw Press Machine – Holly, The product will supply to all over the world, such as: Germany, Germany, Kuala Lumpur, We have more than 100 works in the plant, and we also have a 15 guys work team to service our customers for before and after sales. Good quality is the key factor for the company to stand out from other competitors. Seeing is Believing, want more information? Just trial on its products!

We have been looking for a professional and responsible supplier, and now we find it.

-

One of Hottest for Dosing In Water Treatment -...

-

Lowest Price for Rubber Diffuser - QJB Type So...

-

Factory Price Polymer Dosing Pump - Feeding Me...

-

China Factory for Drum Filter For Koi Pond - Q...

-

China Manufacturer for Drum Filter Ras - QJB T...

-

18 Years Factory Nano Bubble Portable Generator...