Key Features

-

✅Jet Mixer – Guarantees homogeneous dilution of concentrated polymers.

-

✅Accurate Contact Water Meter – Ensures proper dilution ratio.

-

✅Flexible Tank Materials – Customized to application requirements.

-

✅Wide Range of Accessories – Supports diverse installation needs.

-

✅Modular Installation – Flexible positioning of equipment and dosing station.

-

✅Communication Protocols – Supports Profibus-DP, Modbus, and Ethernet for seamless integration with centralized control systems.

-

✅Ultrasonic Level Sensor – Contactless and reliable level detection in the dosing chamber.

-

✅Dosing Station Integration – Strong compatibility with post-preparation dosing systems.

-

✅Engineered to Order – Tailored solutions based on customer-specific dosing requirements, such as polymer feed rate (kg/h), solution concentration, and maturation time.

Typical Applications

-

✔️Coagulation and flocculation in wastewater treatment and drinking water plants

-

✔️Polymer feed for sludge thickening and dewatering

-

✔️Efficient operation in chemical dosing systems for industrial and municipal facilities

-

✔️Suitable for use with polymer dosing pumps, chemical metering pumps, and automatic chemical dosing systems

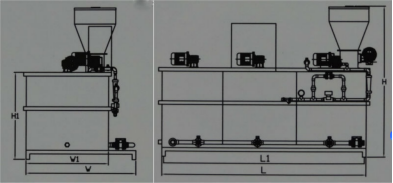

Technical Parameters

| Model/Parameter | HLJY500 | HLJY1000 | HLJY1500 | HLJY2000 | HLJY3000 | HLJY4000 | |

| Capacity(L/H) | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | |

| Dimension(mm) | 900*1500*1650 | 1000*1625*1750 | 1000*2240*1800 | 1220*2440*1800 | 1220*3200*2000 | 1450*3200*2000 | |

| Powder Conveyor Power (KW) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | |

| Paddle Dia (φmm) | 200 | 200 | 300 | 300 | 400 | 400 | |

| Mixing Motor | Spindle Speed (r/min) | 120 | 120 | 120 | 120 | 120 | 120 |

| Power (KW) |

0.2*2 | 0.2*2 | 0.37*2 | 0.37*2 | 0.37*2 | 0.37*2 | |

| Inlet Pipe Dia DN1(mm) |

25 | 25 | 32 | 32 | 50 | 50 | |

| Outlet Pipe Dia DN2(mm) |

25 | 25 | 25 | 25 | 40 | 40 | |