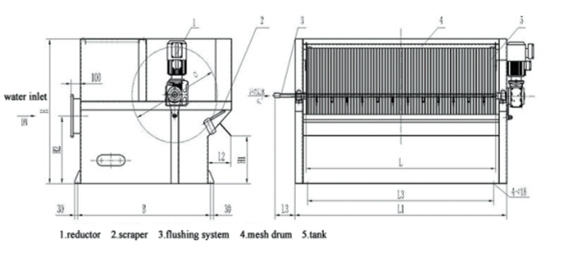

Factory making Mechanical Fine Screen - Mechanical External Feed Rotary Drum Filter Screen – Holly Detail:

Product Features

1.The material is high-strength and corrosion-resistant stainless steel; Less used field area; Convenient construction; It can be directly fixed with expansion bolts without channel construction; Inlet and outlet water can be connected with pipes.

2.The screen will not be blocked by waste solid because the machine is inverted trapezoid cross section

3.The machine is controlled by adjustable-speed motor, which can maintain optimum working condition according to water flow.

4.Special washing device can brush away the impurities on the surface of screen, after twice internal brush, it will achieve the best cleaning effect.

Typical Applications

This is a kind of advanced solid-liquid separation device in water treatment, which can continuously and automatically remove debris from wastewater for sewage pretreatment. It is mainly used in municipal sewage treatment plants, residential quarters sewage pretreatment devices, municipal sewage pumping stations, waterworks and power plants, also it can widely be applied to water treatment projects of various industries, such as textile, printing and dyeing, food, fishery, paper, wine, butchery, curriery etc.

Technical Parameters

| Model | Screen Size | Power | Material | Backwash water | Dimension(mm) | |

| Flow m3/h | Pressure MPa | |||||

| HlWLW-300 | φ300*500mm Space:0.15-5mm |

0.55KW | SS304 | 2.5-3 | ≥0.4 | 760*700*1200 |

| HlWLW-400 | φ400*600mm Space:0.15-5mm |

0.55KW | SS304 | 2.5-3 | ≥0.4 | 860*800*1300 |

| HlWLW-500 | φ500*750mm Space:0.15-5mm |

0.75KW | SS304 | 2.5-3 | ≥0.4 | 1050*900*1500 |

| HlWLW-600 | φ600*900mm Space:0.15-5mm |

0.75KW | SS304 | 3.5-4 | ≥0.4 | 1160*1000*1500 |

| HlWLW-700 | φ700*1000mm Space:0.15-5mm |

0.75KW | SS304 | 3.5-4 | ≥0.4 | 1260*1100*1600 |

| HlWLW-800 | φ800*1200mm Space:0.15-5mm |

1.1KW | SS304 | 4.5-5 | ≥0.4 | 1460*1200*1700 |

| HlWLW-900 | φ900*1350mm Space:0.15-5mm |

1.5KW | SS304 | 4.5-5 | ≥0.4 | 1600*1300*1800 |

| HlWLW-1000 | φ1000*1500mm Space:0.15-5mm |

1.5KW | SS304 | 4.5-5 | ≥0.4 | 1600*1300*1800 |

Product detail pictures:

Related Product Guide:

Adhering into the theory of "quality, services, efficiency and growth", now we have gained trusts and praises from domestic and international shopper for Factory making Mechanical Fine Screen - Mechanical External Feed Rotary Drum Filter Screen – Holly, The product will supply to all over the world, such as: Jamaica, Norwegian, Chile, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to offer you good quality products and the best service. We are looking forward to serving you.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

-

OEM Manufacturer Continuous Screw Press - QJB ...

-

professional factory for Multi Rake Screen - Q...

-

China OEM Screw Sludge Dewatering Machine - Ma...

-

Europe style for Oxygen Aerator - QJB Type Sol...

-

Discount Price Epdm Fine Bubble Diffuser - Was...

-

Wholesale Price China Rotary Drum Screen Workin...