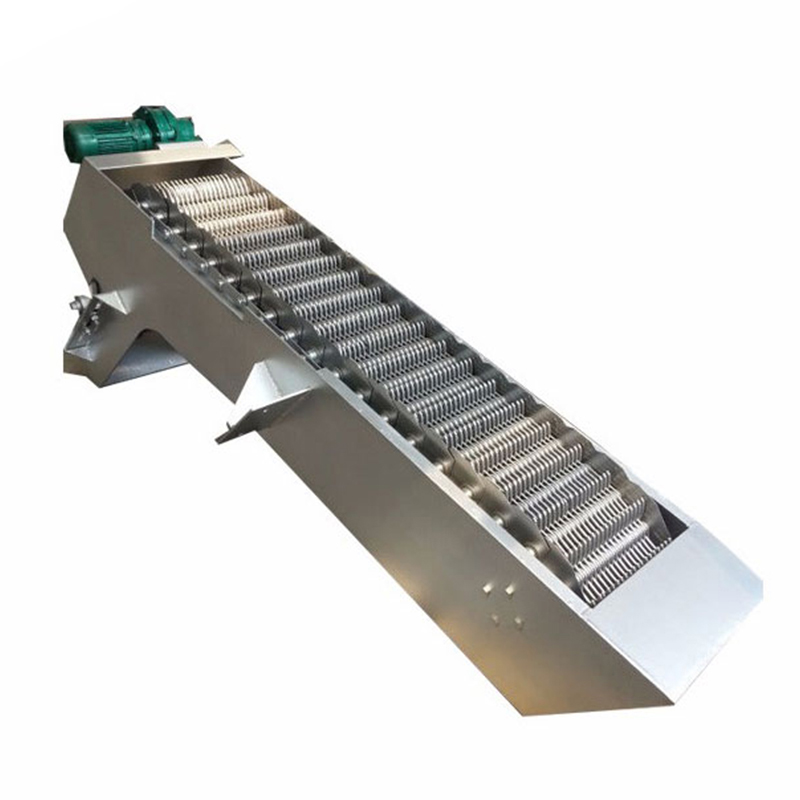

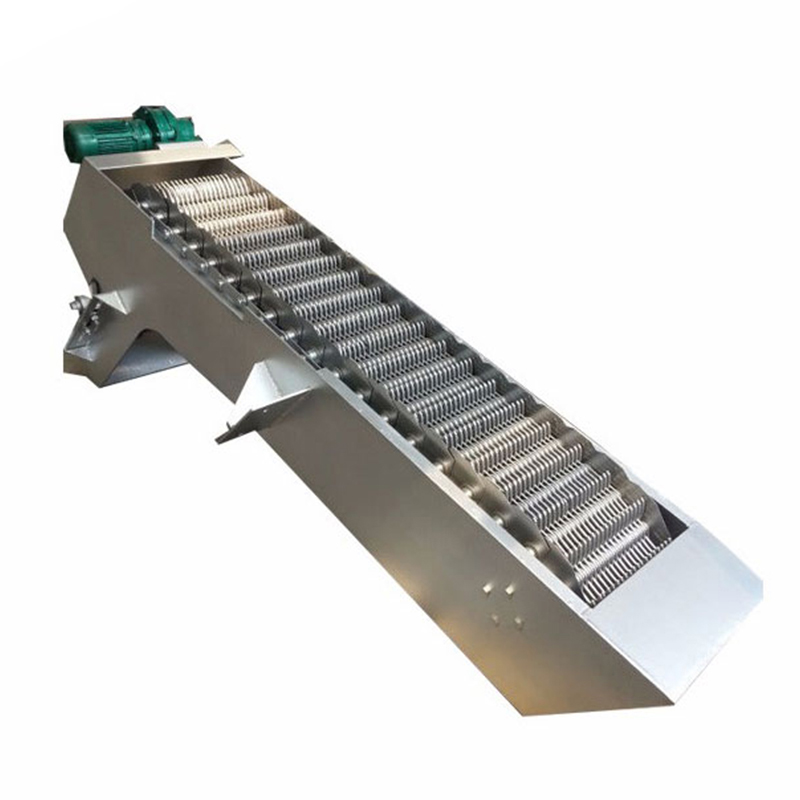

Factory making Mechanical Fine Screen - Auto Wastewater Pretreatment Machine Mechanical Bar Screen – Holly Detail:

Details

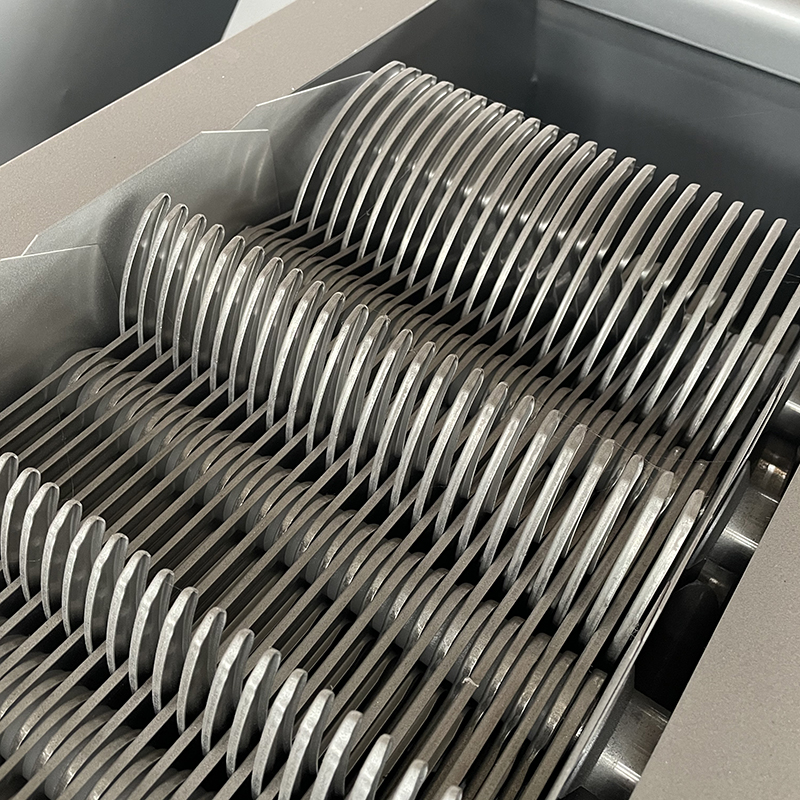

Product Features

1.The driving unit is directly driven by cycloidal gear reducer or helical gear reducer which shows the nature of working stability, low noise, big load capability and high efficiency in conveying.

2.Simple structure with compact size, easy to install and move. Device can self-clean up while working, easy to maintain.

3.Easy to operate, can be controlled directly on the spot or remote.

4.Include overload protection device, machine will shut down automatically when malfunction happens to avoid damage.

5.When the device width exceeds 1500mm, will be made into parallel machine to ensure the overall strength.

Typical Applications

This is a kind of advanced solid-liquid separation device in water treatment, which can continuously and automatically remove debris from wastewater for sewage pretreatment. It is mainly used in municipal sewage treatment plants, residential quarters sewage pretreatment devices, municipal sewage pumping stations, waterworks and power plants, also it can widely be applied to water treatment projects of various industries, such as textile, printing and dyeing, food, fishery, paper, wine, butchery, curriery etc.

Technical Parameters

| Model /Parameter | HLCF-500 | HLCF-600 | HLCF-700 | HLCF-800 | HLCF-900 | HLCF-1000 | HLCF-1100 | HLCF-1200 | HLCF-1300 | HLCF-1400 | HLCF-1500 | ||

| Device Width B(mm) | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 | ||

| Channel Width B1(mm) | B+100 | ||||||||||||

| Effective Grille Spacing B2(mm) | B-157 | ||||||||||||

| Anchor Bolts Spacing B3(mm) | B+200 | ||||||||||||

| Total Width B4(mm) | B+350 | ||||||||||||

| Teeth Spacing b(mm) | t=100 | 1≤b≤10 | |||||||||||

| t=150 | 10<b≤50 | ||||||||||||

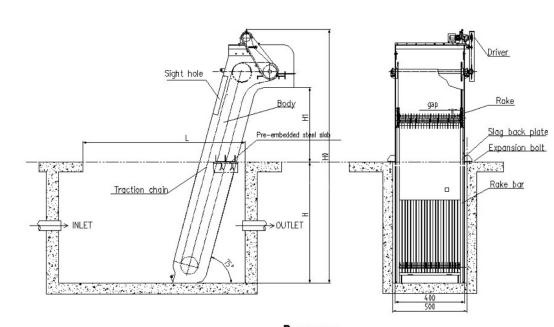

| Installing Angle α(°) | 60-85 | ||||||||||||

| Channel Depth H(mm) | 800-12000 | ||||||||||||

| Height Between Discharge Port and Platform H1(mm) | 600-1200 | ||||||||||||

| Total Height H2(mm) | H+H1+1500 | ||||||||||||

| Back Rack Height H3(mm) | t=100 | ≈1000 | |||||||||||

| t=150 | ≈1100 | ||||||||||||

| Screen Speed v(m/min) | ≈2.1 | ||||||||||||

| Motor Power N(kw) | 0.55-1.1 | 0.75-1.5 | 1.1-2.2 | 1.5-3.0 | |||||||||

| Head Loss(mm) | ≤20(no jam) | ||||||||||||

| Civil Load | P1(KN) | 20 | 25 | ||||||||||

| P2(KN) | 8 | 10 | |||||||||||

| △P(KN) | 1.5 | 2 | |||||||||||

Note:Pis calculated by H=5.0m,for every 1m H increased,then P total=P1(P2)+△P

t:rake tooth pitch coarse:t=150mm

fine:t=100mm

| Model /Parameter | HLCF-500 | HLCF-600 | HLCF-700 | HLCF-800 | HLCF-900 | HLCF-1000 | HLCF-1100 | HLCF-1200 | HLCF-1300 | HLCF-1400 | HLCF-1500 | ||

| Flow Depth H3(m) | 1.0 | ||||||||||||

| Flow Velocity V³(m/s) | 0.8 | ||||||||||||

| Grid Spacing b(mm) | 1 | Flow Rate Q(m³/s) | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.08 | 0.09 | 0.10 | 0.11 | 0.12 |

| 3 | 0.07 | 0.09 | 0.10 | 0.12 | 0.14 | 0.16 | 0.18 | 0.20 | 0.22 | 0.24 | 0.26 | ||

| 5 | 0.09 | 0.11 | 0.14 | 0.16 | 0.18 | 0.21 | 0.23 | 0.26 | 0.28 | 0.31 | 0.33 | ||

| 10 | 0.11 | 0.14 | 0.17 | 0.21 | 0.24 | 0.27 | 0.30 | 0.33 | 0.37 | 0.40 | 0.43 | ||

| 15 | 0.13 | 0.16 | 0.20 | 0.24 | 0.27 | 0.31 | 0.34 | 0.38 | 0.42 | 0.45 | 0.49 | ||

| 20 | 0.14 | 0.17 | 0.21 | 0.25 | 0.29 | 0.33 | 0.37 | 0.41 | 0.45 | 0.49 | 0.53 | ||

| 25 | 0.14 | 0.18 | 0.22 | 0.27 | 0.31 | 0.35 | 0.39 | 0.43 | 0.47 | 0.51 | 0.55 | ||

| 30 | 0.15 | 0.19 | 0.23 | 0.27 | 0.32 | 0.36 | 0.40 | 0.45 | 0.49 | 0.53 | 0.57 | ||

| 40 | 0.15 | 0.20 | 0.24 | 0.29 | 0.33 | 0.38 | 0.42 | 0.46 | 0.51 | 0.55 | 0.60 | ||

| 50 | 0.16 | 0.2 | 0.25 | 0.29 | 0.34 | 0.39 | 0.43 | 0.48 | 0.52 | 0.57 | 0.61 | ||

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for Factory making Mechanical Fine Screen - Auto Wastewater Pretreatment Machine Mechanical Bar Screen – Holly, The product will supply to all over the world, such as: Sevilla, Venezuela, Latvia, We are very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

-

Factory Outlets Micro Nano Bubble Generator - ...

-

Hot New Products Membrane Air Diffuser - QJB T...

-

2021 Latest Design Pond Air - QJB Type Solid L...

-

Professional China Disc Diffuser Aerator - QJB...

-

Top Suppliers Pvc Tube Settler Media - Increas...

-

Reasonable price Air Stone Disc Bubble Diffuser...