Factory directly supply Membrane Diffuser Aeration - Increase Oxygen Pump QXB Centrifugal Type Submersible Aerator – Holly Detail:

Products Description

The QXB submersible aerator is used in aeration tanks and aeration sedimentation tanks of sewage treatment plants to aerate and mix the mixture of sewage and sludge, and perform biochemical treatment of sewage or aeration in aquaculture ponds. The intake air volume is 35~320m3/h, the oxygen increase capacity is 1.8~24kg02/h, the motor power is 1.5~22kW.

Working Principle

Working Conditions

1. Medium Temperature: ≤40℃

2. PH: 5-9

3. Liquid Density:≤1150kg/m3

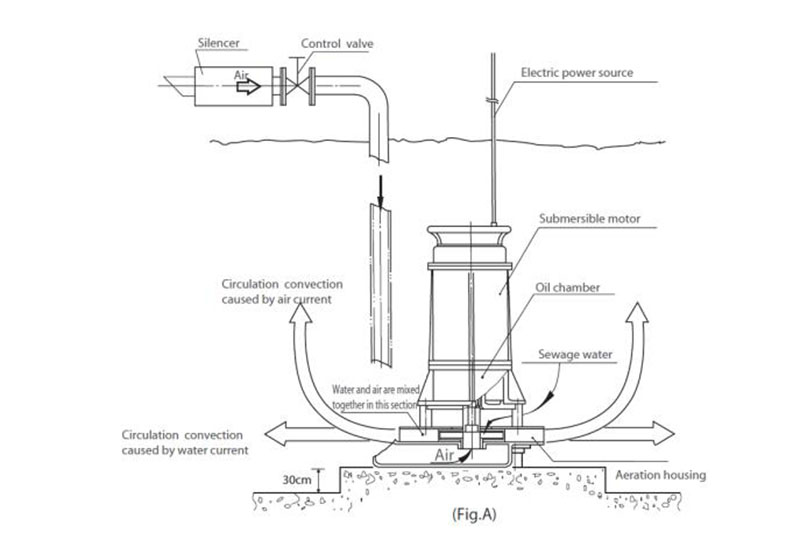

The structure of QXB submersible aerator is directly connected (Fig.A),the rotating impeller generates a centrifugal force in the water, and a negative pressure zone is formed around the impeller through the centrifugal force, so air is sucked in through the intake pipe, the sucked air and water are mixed in the aeration housing, and then this good uniform mixture is automatically discharged from the discharge port .

Products Features

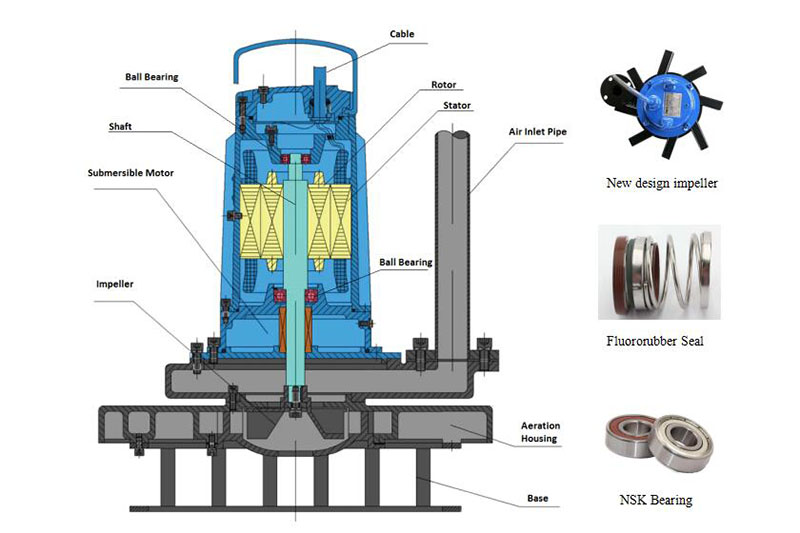

1. Submersible motor directly drive, low noise, high efficiency.

2. Unique design for gas mixture chamber with big air intake volume.

3. Motor with double mechanical seal to ensure longer service life.

4. 12-20 rediated outlets, can bring a mass of bubbles.

5. Inlet with mesh, can avoid impeller being blocked by foreign material.

6. Guide rail available for easy installation&maintenance.

7. Stable operation with thermal protection&leakage sensor.

Technical parameters

| Submersible Aerator | ||||||||

| No | Model | power | cuerrent | Voltage | Speed | Max Depth | Standard air intake | Standard oxygen transfer capacity |

| kw | A | V | r/min | m | m3/h | kg02/h | ||

| 1 | QXB-0.75 | 0.75 | 2.2 | 380 | 1470 | 1.5 | 10 | 0.37 |

| 2 | QXB-1.5 | 1.5 | 4 | 380 | 1470 | 2 | 22 | 1 |

| 3 | QXB-2.2 | 2.2 | 5.8 | 380 | 1470 | 3 | 35 | 1.8 |

| 4 | QXB-3 | 3 | 7.8 | 380 | 1470 | 3.5 | 50 | 2.75 |

| 5 | QXB-4 | 4 | 9.8 | 380 | 1470 | 4 | 75 | 3.8 |

| 6 | QXB-5.5 | 5.5 | 12.4 | 380 | 1470 | 4.5 | 85 | 5.3 |

| 7 | QXB-7.5 | 7.5 | 17 | 380 | 1470 | 5 | 100 | 8.2 |

| 8 | QXB-11 | 11 | 24 | 380 | 1470 | 5 | 160 | 13 |

| 9 | QXB-15 | 15 | 32 | 380 | 1470 | 5 | 200 | 17 |

| 10 | QXB-18.5 | 18.5 | 39 | 380 | 1470 | 5.5 | 260 | 19 |

| 11 | QXB-22 | 22 | 45 | 380 | 1470 | 6 | 320 | 24 |

| Installation Dimensions | ||||||||

| Model | A | DN | B | E | F | H | ||

| QXB-0.75 | 390 | DN40 | 405 | 65 | 165 | 465 | ||

| QXB-1.5 | 420 | DN50 | 535 | 200 | 240 | 550 | ||

| QXB-2.2 | 420 | DN50 | 535 | 200 | 240 | 615 | ||

| QXB-3 | 500 | DN50 | 635 | 205 | 300 | 615 | ||

| QXB-4 | 500 | DN50 | 635 | 205 | 300 | 740 | ||

| QXB-5.5 | 690 | DN80 | 765 | 210 | 320 | 815 | ||

| QXB-7.5 | 690 | DN80 | 765 | 210 | 320 | 815 | ||

| QXB-11 | 720 | DN100 | 870 | 240 | 400 | 1045 | ||

| QXB-15 | 720 | DN100 | 870 | 240 | 400 | 1045 | ||

| QXB-18.5 | 840 | DN125 | 1050 | 240 | 500 | 1100 | ||

| QXB-22 | 840 | DN125 | 1050 | 240 | 500 | 1100 | ||

Product detail pictures:

Related Product Guide:

Our firm sticks on the theory of "Quality will be the life in the enterprise, and status could be the soul of it" for Factory directly supply Membrane Diffuser Aeration - Increase Oxygen Pump QXB Centrifugal Type Submersible Aerator – Holly, The product will supply to all over the world, such as: Greek, Bahrain, San Diego, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, make sure you do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!

-

Top Suppliers Screw Grit Classifier - QJB Type...

-

China Manufacturer for Ozone Nano Bubble Water ...

-

New Fashion Design for Solenoid Dosing Pump - ...

-

China Factory for Drum Filter For Koi Pond - Q...

-

High reputation Filter Rotary - Increase Oxyge...

-

Short Lead Time for Diy Micro Nano Bubble Gener...