Product Features

-

✅ Wide Capacity Range: Single-unit flow capacity from 1 to 100 m³/h, suitable for both small-scale and large-scale wastewater treatment projects, especially for global export markets.

-

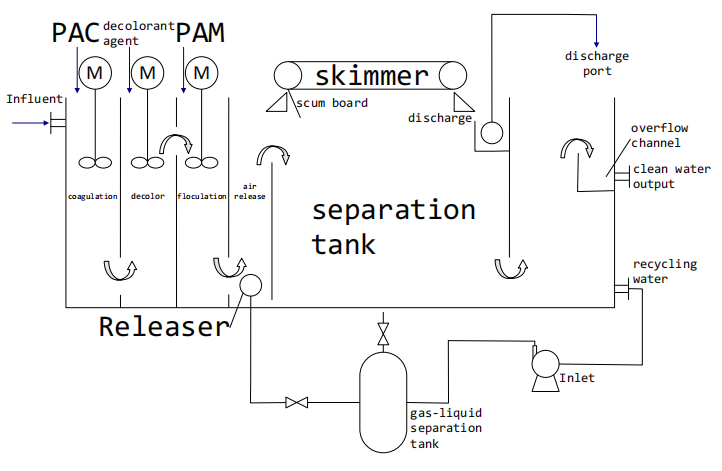

✅ Recycle Flow DAF Technology: Enhanced efficiency through recirculated pressurized water, ensuring stable air saturation and optimal bubble formation.

-

✅ Advanced Pressurization System: Generates a dense cloud of fine microbubbles to maximize contact with suspended solids and oils.

-

✅ Custom-Engineered Designs: Tailored DAF systems available based on specific wastewater characteristics and target pollutant removal levels. Adjustable recycle flow ratios ensure consistent performance.

-

✅ Adjustable Sludge Skimming: Stainless steel chain-type skimmer accommodates varying sludge volumes, ensuring effective and consistent sludge removal.

-

✅ Compact and Integrated Design: Optional coagulation, flocculation, and clean water tanks integrated into the DAF unit to minimize installation space and reduce capital cost.

-

✅ Automated Operation: Remote monitoring and automatic control system enhance operational safety and efficiency.

-

✅ Durable Construction Materials:

① Epoxy-coated Carbon Steel

② Epoxy-coated Carbon Steel with FRP lining

③ Corrosion-resistant Stainless Steel 304 or 316L for harsh environments

Typical Applications

DAF systems are versatile and widely used across industrial and municipal sectors for various wastewater treatment objectives, including:

-

✔️Product Recovery & Reuse: Reclaims valuable materials from process water, reducing waste and enhancing resource efficiency.

-

✔️Pretreatment for Sewer Discharge Compliance: Ensures treated effluent meets local environmental discharge regulations.

-

✔️Biological System Load Reduction: Removes oils, solids, and grease before biological treatment, improving downstream efficiency.

-

✔️Final Effluent Polishing: Enhances the clarity of biologically treated effluent by removing remaining suspended particles.

-

✔️Removal of Oils, Grease, and Silt: Particularly effective for wastewater containing emulsified fats and fine solids.

Widely Applied In:

-

✔️Meat, Poultry & Seafood Processing Plants: Removes blood, fat, and protein residues.

-

✔️Dairy Production Facilities: Separates milk solids and grease from process water.

-

✔️Petrochemical Industry: Treats oily wastewater and separates hydrocarbons.

-

✔️Pulp & Paper Mills: Removes fibrous materials and ink residues.

-

✔️Food & Beverage Manufacturing: Manages organic contaminants and cleaning byproducts.

Technical Parameters

| Model | Capacity (m³/h) |

Dissolved air water volume(m) | Main motor power(kW) | Mixer power(kW) | Scraper power(kW) | Air compressor power(kW) | Dimensions (mm) |

| HLDAF-2.5 | 2~2.5 | 1 | 3 | 0.55*1 | 0.55 | - | 2000*3000*2000 |

| HLDAF-5 | 4~5 | 2 | 3 | 0.55*2 | 0.55 | - | 3500*2000*2000 |

| HLDAF-10 | 8~10 | 3.5 | 3 | 0.55*2 | 0.55 | - | 4500*2100*2000 |

| HLDAF-15 | 10~15 | 5 | 4 | 0.55*2 | 0.55 | - | 5000*2100*2000 |

| HLDAF-20 | 15~20 | 8 | 5.5 | 0.55*2 | 0.55 | - | 5500*2100*2000 |

| HLDAF-30 | 20~30 | 10 | 5.5 | 0.75*2 | 0.75 | 1.5 | 7000*2100*2000 |

| HLDAF-40 | 35~40 | 15 | 7.5 | 0.75*2 | 0.75 | 2.2 | 8000*2150*2150 |

| HLDAF-50 | 45~50 | 25 | 7.5 | 0.75*2 | 0.75 | 3 | 9000*2150*2150 |

| HLDAF-60 | 55~60 | 25 | 7.5 | 0.75*2 | 1.1 | 4 | 9000*2500*2500 |

| HLDAF-75 | 70~75 | 35 | 12.5 | 0.75*3 | 1.1 | 5.5 | 9000*3000*3000 |

| HLDAF-100 | 95~100 | 50 | 15 | 0.75*3 | 1.1 | 3 | 10000*3000*3000 |